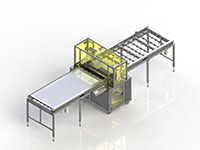

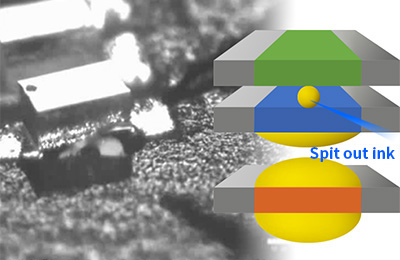

iEHD PRINTER

iEHD PRINTER

-

LCD Repair

- ·The open defect is directly repaired by printing metal ink and can achieve high resolution and high quality electrodes.

- ·Compared with the existing CVD repair-technology, the process can allow high resolution patterns and enhanced step coverage and flexibility.

PATTERN SIZE3μm or more

-

OLED Repair

- ·The open defect is directly repaired by printing metal ink and can achieve high resolution and high quality electrodes.

- ·It can repair 1μm-level patterns, which is the World champion performance.

PATTERN SIZE1.5μm or less

-

uLED Repair

- ·For the defect free micro-LED display, due to the limit of multi-transfer, repair solution is key process in manufacturing. Enjet provides the chip repairing solution for the micro-LED display.

PATTERN SIZE10μm or less

-

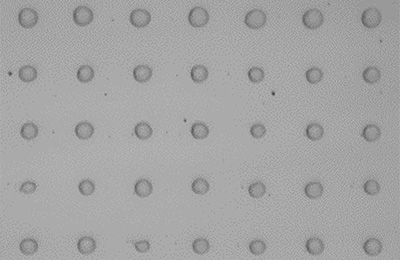

Micro-Precision Bump Printing

- ·Uniform and small features can be printed, which can be less than 10um. It can be applied to bumper fabrication.

PATTERN SIZE10μm or less

-

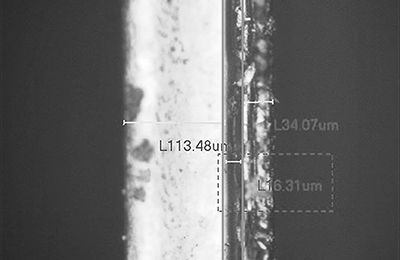

Underfill

- ·Enjet develops innovative underfill solutions for semi-conductor packaging, based on our dispensing technology.

- ·Compared with the conventional method, due to the effect of the electric field, it has the advantage of void-free underfilling performance.

-

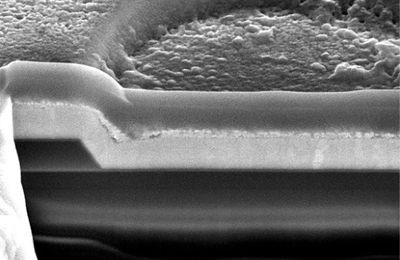

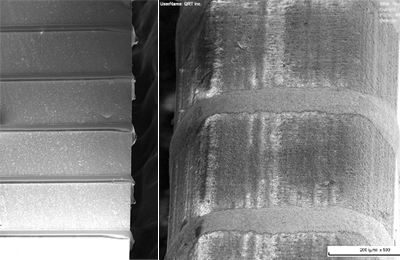

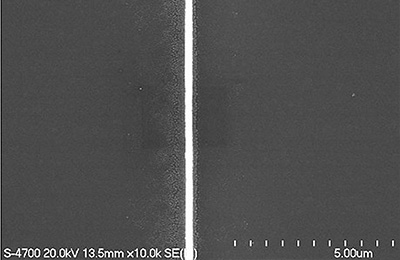

Side Electrode printing

- ·3D edge side electrodes can be successfully fabricated by our solution.

model

-

Bonding & Sealing

- ·Our dispensing technology is being applied to various application areas such as adhesive bonding and sealing.

model

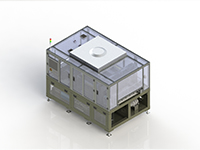

iEHD COATER

iEHD COATER

-

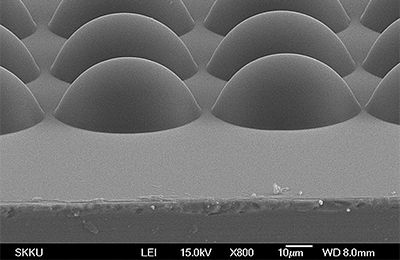

Anti Glare

- ·Enjet has developed solutions for AG coating and applied to customers. EHD spray method can fabricate more uniform films and high yield performance compared with other methods.

-

Anti Finger coating

- ·Anti-finger coatings have been used in many applications such as mobile phones, glasses and displays.

- ·Compared with air and ultrasonic spary coatings, EHD spray coatings can reduce the material usage and achieve a uniform thin film.

-

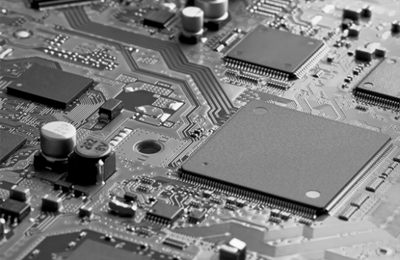

Electromagnetic Interference (EMI) Shielding

- ·The EHD spray method has been applied to the electromagnetic (EMI) shielding of semiconductors and could achieve highly uniform coating layers on 3D chip structure.

-

Conformal Coating

- ·There are many requirements for forming thin films in PCB, chip, display, mobile phones, etc.

- ·Recently, the EHD electrostatic spraying method can uniformly coat the functional materials on entire exposed surfaces of the 3D structure.

model

-

Flux Coating

- ·Flux coating is applied to the surface of the printed wiring board (PWB) or printed circuit board (PCB) before soldering to ensure good adhesion between the solders.

- ·The flux can remove oxide layers, prevent the formation of oxide layers, and improve the quality of the soldering and the electromechanical connection at the interface with the circuit.

- ·EHD spraying methods can carry out thin and uniform coatings for flux applications.

model

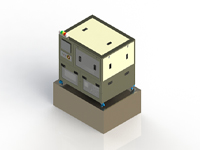

PLASMA

PLASMA

-

Hydrophilic

- ·ENJET has developed Direct RF plasma head technology with high-density plasma capability and applied it to ultra-precision coating machines for many years.

- ·ENJET's plasma solution can stably ignite plasma and carry out the surface treatment at a long distance.

model

-

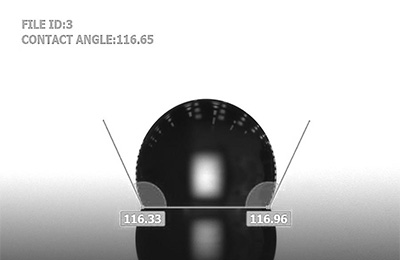

Hydrophobicity

- ·Enjet plasma solution can form a hydrophobic film layer on many surfaces such as wafers, ceramics, and glasses in seconds to minutes.

model

INK

INK

-

Particle-free conductive ink for Bonding

- ·Product : Micro LED

- ·Target : Anode/Cathode Electrode Based on TFT

- ·Pattern Requirement : < 15 ㎛ diameter

model

-

Particle-free conductive ink for electrodes repair

- ·Product : Micro LED

- ·Target : Data Electrode repair

- ·Pattern Requirement : Edge-Electrodes

- ·Repair Efficiency : 100 %

model

-

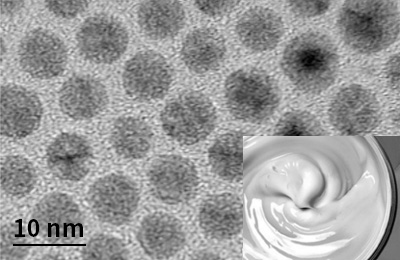

Hybrid conductive ink for fabricating electrodes

- ·LERProduct : Micro LED, LCD TV TFT gate/source electrodes

- ·Target : Electrode fabrication

model

-

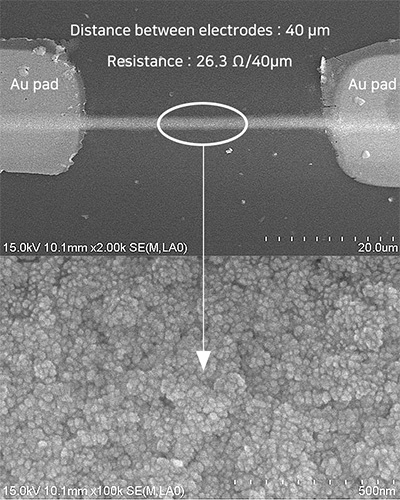

Particle conductive ink for 3D electrodes formation

- ·Direct patterning of edge-electrode using our EHD printer and particle conductive ink

model

-

Particle conductive ink for TFT electrodes formation

- ·High resolution direct patterning of OLED TFT electrode based on nano-particle conductive ink

model

-

Underfill ink for Mini-LED

- ·Thermal curing ink of epoxy base for EHD

- ·Curing temp. 150~200℃/30min

- ·Hard type

model

-

Insulation coating for Micro-LED

- ·Thermal curing ink of epoxy base for EHD

- ·Low curing temp.(~130℃/30min)

- ·Soft type

- ·High transparence

model